TRANSFORMER PART

Mold Transformer

Mold Transformer

SSANGYONG Electric Co.,Ltd.‘s mold transformer, produced in the latest vacuum casting machine and compactly designed, demonstrates high efficiency, flame resistance, short-circuit force, moisture-proof, and easy maintenance and fits for operating machines with fluctuating load variation.

1. Epoxy resin of the excellent flame retarding performance is used to prevent a risk of ignition or explosion in case of arc fire and to secure self-extinguish ability.

2. High-tension coils are used to produce molding in a vacuum state where no bubbles are formed inside the coils and the partial discharge performance is outstanding.

3. Thin aluminum plate conductors whose coefficient of expansion is similar to that of epoxy resin are used to prevent a risk of epoxy molding splitting regardless of temperature changes due to load variation.

4. The latest facilities for vacuum molding and optimal design methods feature the high tolerance of overload within a short time as well as the outstanding electronic mechanical power and lightning shock withstand performance.

5. The latest vacuum molding facilities and outstanding insulating materials are used for vacuum molding to extend the lifespan of transformers. As the highest-level of design and manufacturing technologies are adopted to secure the high efficiency.

Applicable

- General and public facilities (downtown skyscrapers, apartment complexes, hotels, schools, hospitals, other public facilities)

- Manufacturing plants (automotive factories, semiconductor plants, chemical plants, etc.)

- Ship-building and new & renewable energy facilities (LNG ship and electric propulsion ship, wind power system, etc.)

- Special sites (various power plants, airports, subways, high-speed trains, container cranes, etc.)

Rating

- Phase : 1Ø / 3Ø

- Frequency : 50Hz, 60Hz

- High Voltage : 3.3kV, 6.6kV, 22.9kV

- Capacity : 100~3000kVA

- Winding : Aluminum

- Standard IEC, ANSI, NEMA, JEC

- Core : Silicon Steel or Amorphous

Excellent design capability and production technology

Production of highest-level products through introduction of the latest vacuum molding facilities, training of technical workforce, and continued R&D.

Outstanding stability and reliability

Epoxy resin of the excellent flame retarding performance is used to prevent a risk of ignition or explosion in case of arc fire and to secure self-extinguish ability.

Longer lifespan and higher efficiency

s the highest-level of design and manufacturing technologies are adopted to secure the high efficiency.

Constantly Challenging,

Creating a New Future

We are creating a new future by constantly taking on challenges.

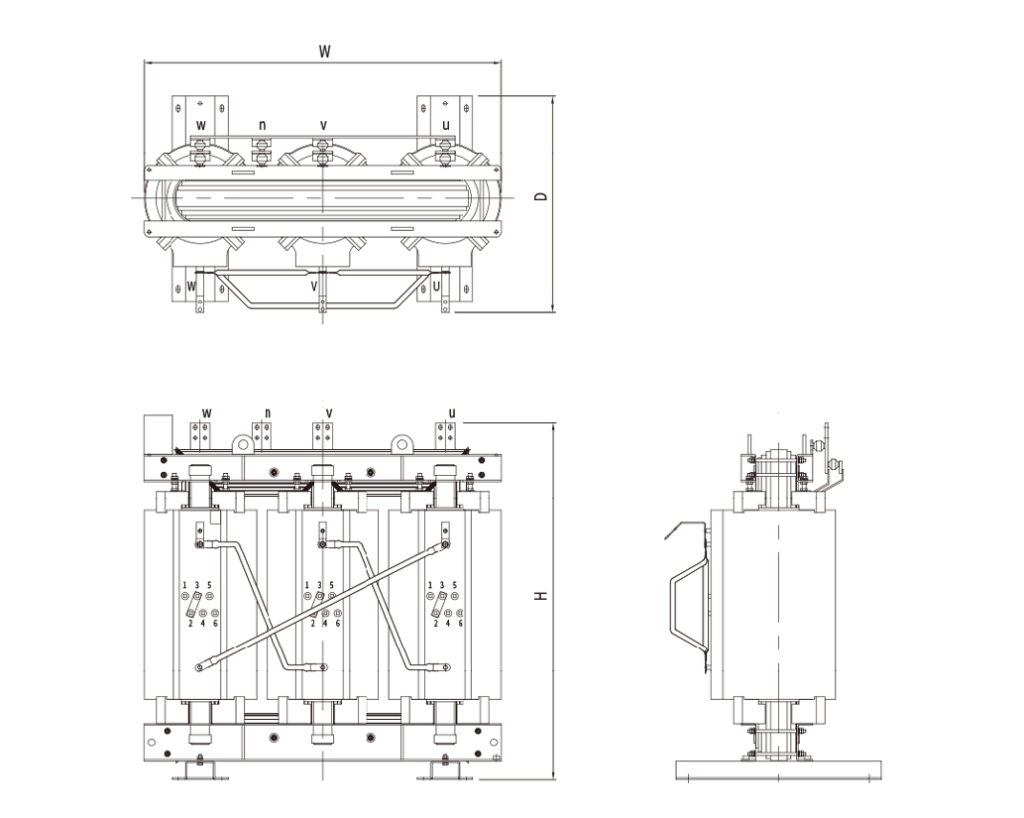

Dimension

SPECIFICATION

Dimension

specification

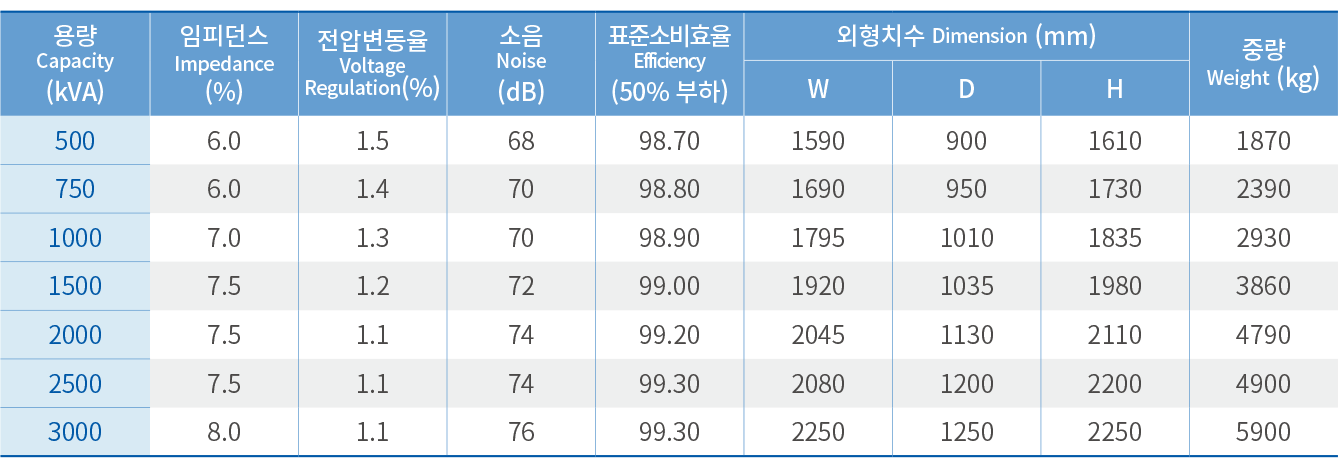

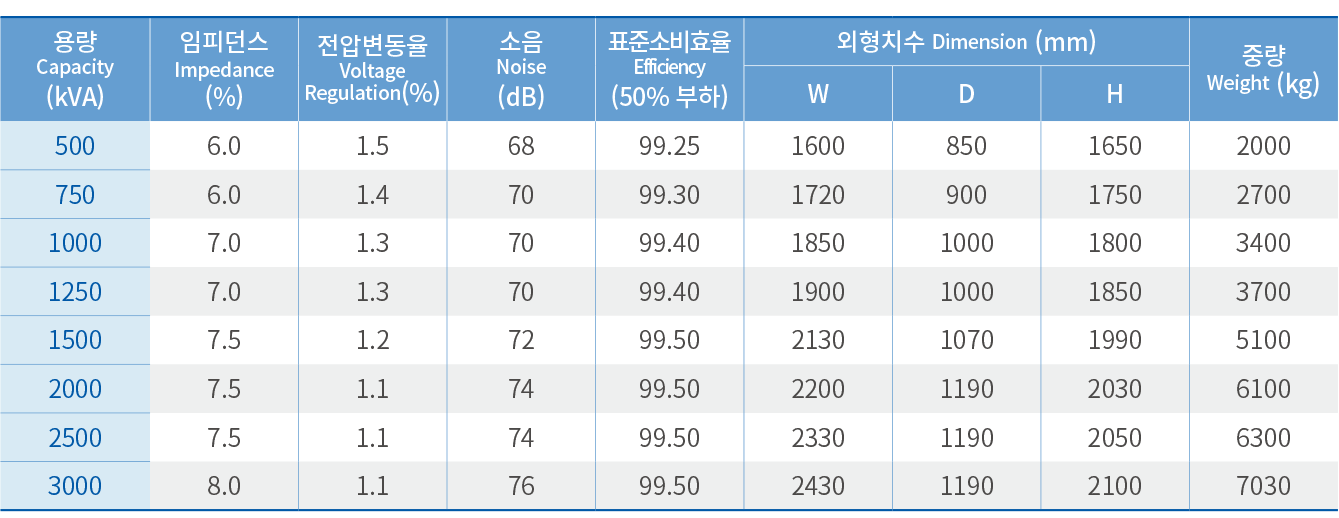

표준소비효율(High Efficiency)

표준소비효율 | High Efficiency (3P 22.9kV / 380-220V)

표준소비효율 | High Efficiency (3P 22.9kV / 6.6 or 3.3V)

표준소비효율 | High Efficiency (3P 6.6 or 3.3kV / 380-220V)

최저소비효율(General Efficiency)

최저소비효율 | General Efficiency (3P 22.9kV / 380-220V)

최저소비효율 | General Efficiency (3P 22.9kV / 6.6 or 3.3V)

최저소비효율 | General Efficiency (3P 6.6 or 3.3kV / 380-220V)